TOKYO, Sep 12, 2023 – (ACN Newswire) – TANAKA Kikinzoku Kogyo K.K. (Head office: Chiyoda-ku, Tokyo; Group CEO: Koichiro Tanaka), which operates an industrial precious metals business as a core company of TANAKA Precious Metals, announced today that it has signed a technical assistance agreement with Chengdu Guangming Paite Precious Metal Co., Ltd., an affiliated company in China, in the area of fuel cell electrode catalyst manufacturing technologies.

|

As part of the agreement, production equipment will be installed at the plant of Ya'an Guangming Paite Precious Metal Co., Ltd., a subsidiary of Chengdu Guangming Paite Precious Metal, with plans to start full-scale production in the summer of 2024. The companies also plan to start production of fuel cell electrode catalysts for the Chinese market by the end of 2025. As a member of TANAKA and with the leading share of the global market for fuel cell electrode catalysts, TANAKA Kikinzoku Kogyo aims to use this agreement to meet the growing domestic demand for fuel cell electrode catalysts in China.

TANAKA's Fuel Cell Electrode Catalysts

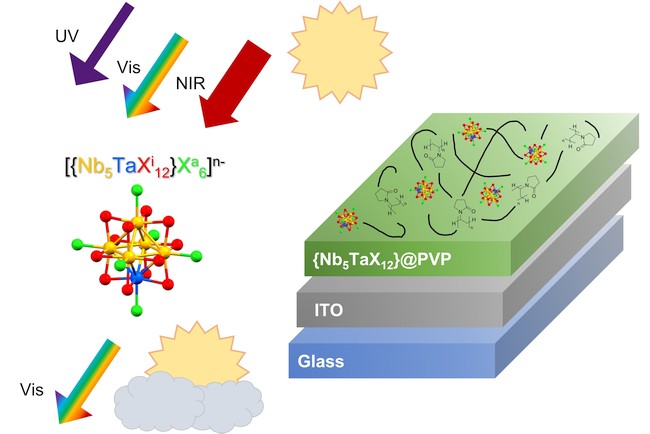

TANAKA's FC Catalyst Development Center, within its Shonan Plant, is currently developing and manufacturing electrode catalysts for polymer electrolyte membrane fuel cells (PEFCs) and polymer electrolyte water electrolysis (PEWE). The company sells highly active, highly durable platinum catalysts and platinum alloy catalysts for PEFC cathodes[1], highly CO-tolerant platinum alloy catalysts and OER catalysts[2] for PEFC anodes[3], and iridium oxide catalysts for PEWE anodes.

PEFCs are used in applications such as fuel cell vehicles (FCVs) and residential-use fuel cells (ENE-FARM), with their use expected to expand in the future to also include buses, trucks, and other commercial vehicles, forklifts and other material handling vehicles, heavy construction machines, robots and other industrial machines, and large stationary equipment. Compact, lightweight, high-output PEFCs employ a chemical reaction between hydrogen and oxygen to generate power, which will make them important devices for the global environment of the future.

One major issue facing the full-scale use of fuel cell batteries is the cost of the platinum they use. TANAKA has been researching precious metal catalysts for more than 40 years, resulting in the development of catalysts that use smaller amounts of precious metals while achieving high performance and high durability. By studying new carrier materials and catalyst post-processing methods and producing more active metal species, the company is currently developing catalysts that are even more suitable for use in fuel cells.

Trends in the Global Fuel Cell Market

In China, government policy continues to drive the development of hydrogen energy and FCVs as strategic industries. The Chinese government is implementing a range of support measures to promote research and development and the expanded use of fuel cell battery technologies. It is also driving the development and adoption of FCVs through subsidies, tax incentives, and other efforts. With other measures, including the development of hydrogen supply infrastructure in cities and along major traffic routes, the country's fuel cell market is expected to grow even further going forward.

In Europe and the United States as well, governments are promoting zero-emission vehicles (ZEVs)[4]. In the EU, as part of the Fit for 55 package of climate change measures adopted by the European Union in April 2023, a bill was adopted to require new passenger vehicles and small commercial vehicles to be zero-emission, in principle, from 2035. (The sale of new vehicles equipped with internal combustion engines will only be accepted after 2035 if they use synthetic fuels (e-fuels)[5].) In the US as well, an executive order was issued in 2021 to require 50% of new car sales to be electric by 2030.

In Japan, the Ministry of Economy, Trade, and Industry has been meeting with representatives of the hydrogen supply industry, automobile manufacturers, logistics companies, local governments, and others since September 2022 to discuss the expanded use of hydrogen in mobility. In an interim summary of discussions in July 2023, it announced that the selection of priority areas for early adoption of trucks and buses that use fuel cells to run will be finalized before the end of this year.

TANAKA will continue to focus on research and development while working to achieve stable supplies of fuel cell electrode catalysts, and as the leading company in the area of fuel cell electrode catalysts, it aims to contribute toward the expansion of fuel cell use and realization of a hydrogen society.

[1] Cathodes: Hydrogen-generation electrodes (air poles) where oxygen reduction reactions take place. This assumes that hydrogen-generation electrodes are being used for water electrolysis (PEWE).

[2] OER catalysts: Catalysts that activate oxygen evolution reactions.

[3] Anodes: Oxygen-generation electrodes (fuel poles) where hydrogen oxidation reactions take place. This assumes that hydrogen-generation electrodes are being used for water electrolysis (PEWE).

[4] Zero-emission vehicles: Electric vehicles (EVs) and fuel cell vehicles (FCVs) that emit no carbon dioxide or other greenhouse gases during operation. In the United States, plug-in electric vehicles (PHEVs) are also considered to be ZEVs.

[5] E-fuels: Petroleum-alternative fuels produced in a chemical reaction between carbon dioxide (CO2) and hydrogen (H2).

About TANAKA Precious Metals

Since its foundation in 1885, TANAKA Precious Metals has built a portfolio of products to support a diversified range of business uses focused on precious metals. TANAKA is a leader in Japan regarding the volumes of precious metals handled. Over the course of many years, TANAKA has not only manufactured and sold precious metal products for industry but also provided precious metals in such forms as jewelry and assets. As precious metals specialists, all Group companies in Japan and around the world collaborate and cooperate on manufacturing, sales, and technology development to offer a full range of products and services. With 5,355 employees, the group's consolidated net sales for the fiscal year ending March 31, 2023, was 680 billion yen.

Global industrial business website

https://tanaka-preciousmetals.com/en/

Product inquiries

TANAKA Kikinzoku Kogyo K.K.

https://tanaka-preciousmetals.com/en/inquiries-on-industrial-products/

Press inquiries

TANAKA Holdings Co., Ltd.

https://tanaka-preciousmetals.com/en/inquiries-for-media/

Press Release: http://www.acnnewswire.com/docs/files/20230912_EN.pdf

Copyright 2023 ACN Newswire. All rights reserved. http://www.acnnewswire.com